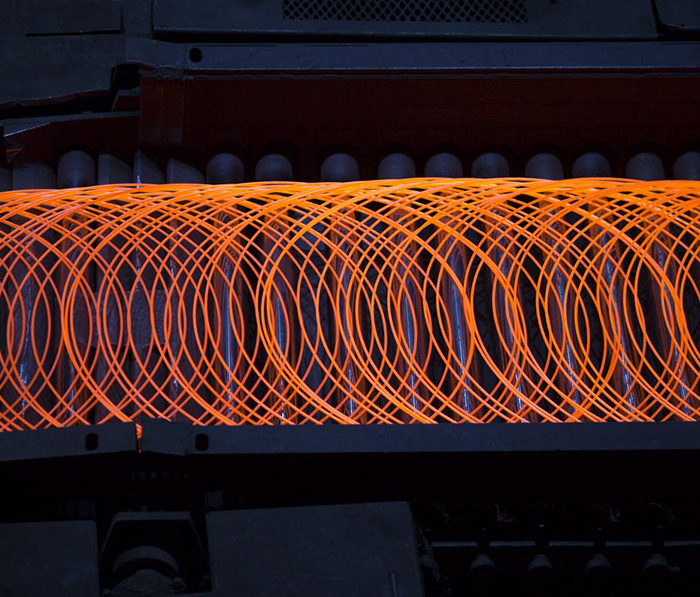

Deep.Meta is helping solve this by applying AI and machine learning to steel producers’ existing data to drive energy efficiency. Doing that we can cut a significant portion of global CO2 emissions.

Agentic Plant Optimisation

Steel producers use Deep.Meta to achieve System Level Optimisation.

Improving yields and energy efficiency without additional hardware.

Steel alone is responsible for 8% of global emissions

We impact the bottom line

That’s because 40% of Steel Production costs are from Energy.

Much of this is currently fossil fuel-based which means driving reduction in Energy and directly cuts CO2 emissions.

300 MWh

energy saved every month

Energy to heat 250 homes a month

>10%

reduction in residence time

180t

CO2 prevented every month

Emissions by 470 cars a month

Yield Improvement

Deep.Meta’s software optimises production by harnessing data from existing sensors at steel plants to enable real-time insights to warn operators of potential defects across the melt shop, caster and rolling mill.

Energy Savings

Our Algorithms are designed to assist producers in minimising the energy to melt or reheat products, helping them achieve significant bottom line savings combined with reduced carbon emissions.

Scheduling

Efficiency of production can be improved significantly through our specialised scheduling algorithms. We help you increase your output capacity by developing optimised, dynamic order schedules.